First. Convection of the glass flow in the kiln

1. Due to the heat dissipation of the kiln body, the temperature difference of the molten glass in the kiln is caused, and the density of the molten glass is inversely proportional to the temperature. The temperature difference will inevitably cause the density difference. When the molten glass of different density exists in various parts of the kiln, the surface layer will be formed. The molten glass flows from the high temperature to the low temperature side, and the low temperature molten glass flows from the deep layer to the high temperature side. The greater the temperature gradient of the molten glass, the more intense the convection.

2. Feeding thrust. After the batch material is put into the glass melting furnace, the batch material is pushed from the feeding port to the middle of the melting furnace by the thrust of the feeder, and the natural batch material will drive the surface glass liquid under the material layer to move forward.

3. At the outlet of the glass liquid, the liquid level is low caused by the forming and drawing, and the surface flow is generated.

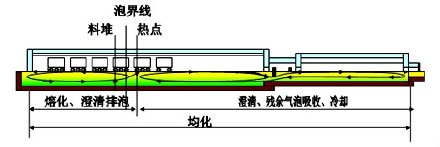

Flow diagram of molten glass in the kiln

The convection from the hot spot to the feeding port is called circulation one.

The convection from the hot spot to the neck of the card is called circulation two.

The convection from the hot spot to the cooling part and the runner is called the circulation three.

The depth of the card neck water bag directly controls the amount of liquid glass that enters the cooling part. The deeper the water bag is inserted, the less the liquid glass that enters the cooling part and the faster the cooling speed is.

The following two points should be considered for the influence of the card neck water bag on melting. One is the energy consumption of melting. The second is the melting and clarification of glass.

Second. The influence of the neck opening on the energy consumption, clarification and homogenization of glass melting

1. Energy consumption: After the card neck water bag is deepened, the supply and return flow of the cooling part is reduced, the return flow of the cooling part is reduced, the low-temperature glass liquid required to be heated for melting is reduced, the overall temperature of the glass liquid in the melting pool rises, and the melting speed increases. The clarification temperature rises and the energy consumption is reduced. But on the other hand, the amount of hot glass liquid entering the cooling part is less, the cooling speed is increased, and the temperature of the runner is constant, and it must meet the requirements of molding. This requires increasing the temperature of the small furnace to meet the needs of molding. Increase energy consumption. A kiln uses water bags of different depths, and the insertion depth of the water bag gradually increases from shallow. The energy consumption changes from high energy consumption to gradually increase after reaching the lowest point. It is a parabolic change curve.

2. Clarification of glass liquid:

The clarification of glass, when the neck opening is reduced, the amount of molten glass entering the cooling part of the forming flow is reduced, the reflux rate of the cooling part is reduced, the overall temperature of the melting part of the molten glass rises, and the clarification and defoaming ability of the molten glass at high temperatures The increase is conducive to the high temperature clarification of the molten glass. The glass clarification process should be divided into two parts, one is the high-temperature bubble clarification of the glass; the other is the absorption of residual bubbles during the cooling process of the glass, and the cooling microbubbles absorb and clarify.

Decreasing the opening of the sling neck, the high-temperature clarification effect of the glass liquid is obviously improved, but the change of the opening of the sling neck will inevitably change the cooling temperature curve of the glass liquid. The change of the cooling curve has a greater influence on the absorption of microbubbles. The clarification effect should be tested in various aspects, and the test will give a good clarification effect.

The normal glass liquid cooling temperature curve should be uniform and stable, without abrupt curve, as shown in the figure below:

If the temperature reduces the opening of the neck, that is, increases the insertion depth of the neck, the glass liquid temperature curve will produce a sharp temperature change point at the neck, as shown in the figure below, thereby changing the heat history absorbed by the microbubbles during the cooling process of the liquid glass. Microbubbles are difficult to be absorbed by the molten glass, and they exist in the finished product and affect the quality of the glass.

The molten glass produces a sharp cooling section at the neck, where the sulfur dioxide gas in the gas microbubbles in the molten glass recomb Liquid absorption.

3. The influence of the card opening degree change on the glass homogenization effect

The change of the neck opening degree is basically similar to the clarification effect. The opening degree decreases, the temperature of the melting part increases, and the viscosity of the glass liquid decreases, which is conducive to the homogenization of the glass liquid. The mixing effect reduces the homogenization effect.

Third, the structure of the card neck water bag

When designing the card-neck deep-layer water bag, we must first consider the role of the water bag. Your purpose is different and the structure is different. Under normal circumstances, our main purpose is to control the supply and return flow of the glass into and out of the cooling section. The second is to block the scum in the surface flow;

Since the main function of inserting the card neck water bag is to control the supply and return flow into the cooling part, we should reduce the cooling intensity of the water bag as much as possible when designing the water bag, and reduce the cooling of the glass liquid by the card neck water bag. Its advantages It reduces the violent cooling effect of the chuck neck, so that the glass liquid passing through the chuck neck obtains a uniform cooling process, and reduces the difficulty of microbubble absorption caused by the violent cooling of the glass liquid. The cooling of the molten glass mainly relies on controlling the amount of molten glass entering the cooling section, that is, reducing the amount of heat entering the cooling section per unit time, so as to increase the cooling effect of the molten glass and control the appropriate temperature for entering the molten glass. (When the heat dissipation state of the recooling part remains unchanged, the amount of molten glass entering the cooling part will decrease, the running speed of the glass will decrease, the residence time will increase, and the temperature gradient of the molten glass per unit distance in the cooling part will increase)

The structure of the water bag is best to adopt the structure shown in the figure below. The gap is opened in the middle of the water bag. When the water bag is inserted into the glass liquid, the glass liquid in the gap will condense and become a fixed layer of glass liquid. Reduce the temperature gradient of the molten glass here. Another big advantage is that when replacing the neck water protector, due to the existence of this gap, it can effectively prevent the crystal glass attached to the water bag from falling off in the glass liquid, reducing the quality loss caused by the replacement of the water bag.

Production of water bag:

There is a certain degree of knowledge in the production of water bag, which is not completed by just welding according to the picture. He has a deep knowledge. The quality of the water bag is related to many factors such as the steel used, welding rod, welding method and so on.

1. The choice of steel: we generally use seamless steel pipe welding (round steel) water ladle, or use cold-rolled steel plate to cut and weld. It is best not to use square steel. Due to the production process of square steel, right-angle corners will be formed. Tiny cracks, after the water bag penetrates into the molten glass, harmful impurities such as metal ions and sulfur in the glass will penetrate into the micro cracks, causing the metal to crystallize and causing the water bag to leak.

2. The welding rod of the welding water bag should be made of the same material to ensure the welding quality.

3. The design of the water bag should ensure the smooth flow of water, no dead angle area and eddy current area, avoid air resistance, local high temperature spots, and affect the service life.