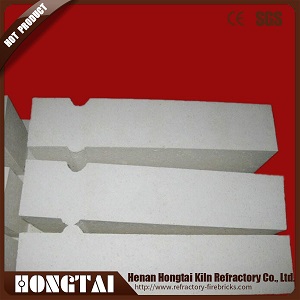

Sillimanite bricks are refractory bricks with good characteristics, which are prepared from sillimanite minerals by the high-temperature firing method or slurry casting method. Sillimanite is converted into mullite and free silica after high-temperature calcination. It is generally produced by the high-temperature firing method and slurry casting method.

Sillimanite bricks are a natural high-grade refractory mineral, which has the characteristics of low thermal expansion rate, resistance to corrosion from metallurgical slag and various glass liquids, and good high temperature wear resistance. Its physical and chemical properties are better than those of high-alumina bricks, with refractoriness of 1770-1830 °C, and a load softening starting point of 1500-1650 °C. It is mainly used for the molding of liquid holes in glass pool kilns, blast furnace lining, furnace throat,s and ceramic industrial kiln furniture. The refractory materials based on natural sillimanite also have these advantages. Therefore, sillimanite refractories are widely used in metallurgy, chemical, and building materials industries.

A certain factory in my country is a professional manufacturer of glass refractories. Through external technical exchanges and inspections of relevant glass manufacturers, we fully understand the superiority of natural sillimanite refractories. According to the needs of the daily-use glass industry, the natural sillimanite refractory material for the feeder and feeder of the daily-use glass kiln was first developed, put into mass production, and passed the provincial appraisal. Then completed the "Seventh Five-Year" research project of the State Building Materials Bureau, sillimanite refractories for float glass in baths. Over the years, it has won high praise from users for its high refractoriness, high thermal shock stability, and high erosion resistance, and has achieved huge social and economic benefits.

1 High temperature resistant anti-wear coating;

2 sillimanite refractory balls;

3 Styrene method kaolin-sillimanite heat-insulating refractory products;

4 The high-strength unshaped refractory material is used for refractory mud for building high-temperature kilns;

5 Rare earth composite silicon carbide material;

6 A composite heat-insulating high-temperature refractory coating;

7 Refractory castable with high-temperature self-enhancing effect.

1 Property of sillimanite

Jixi Sandaogou sillimanite mine is open-pit mining. Linear sillimanite is distributed in crystalline granite, and the grade is generally 10%~20%. The ore is crushed, ball-milled, and then floated out. The ore body mainly contains quartz and sillimanite, followed by potassium feldspar, mica, ilmenite, and graphite, etc. The recoverable reserves are 30 million tons, and the annual output of sillimanite concentrate is 4,000 tons.

The transformation temperature of Jixi sillimanite is relatively high, and the linear expansion of the transformation front is very small. When heated to 1 545 ℃, it decomposes into quartz and mullite according to the following formula, accompanied by a certain volume expansion.

2 The choice of aggregate

It can be seen from the particle size composition of Sillimanite bricks that most of the coarse particles are below 0.2mm, which is too fine for coarse particles and too coarse for fine powder, which brings difficulties to reasonable particle grading. The production cost is greatly increased, so appropriate coarse particles must be selected to meet the requirements of production and product performance. A mineral with similar properties to sillimanite is mullite. The thermal expansion rate of synthetic mullite is 0.53% at 1 200 ℃, which is very close to the thermal expansion rate of natural sillimanite. Therefore, it is more reasonable to introduce synthetic mullite coarse particles into sillimanite products. After comparison, Hunan Chenxi synthetic mullite is selected, and the mullite crystal phase content is ≥95%.

3 Choice of binders

The physical and chemical properties of the binder for sillimanite products are best close to that of natural sillimanite, especially the chemical composition and thermal expansion coefficient, which are basically consistent with those of natural sillimanite. Fixed high aluminum binder.

Previous Post:Fused Magnesia Chrome Brick

Next Post:Use of silica bricks

Application of high-aluminum refractories in high-temperature industries

Classification of refractory properties and their application areas

High alumina bricks commonly used in industrial kilns