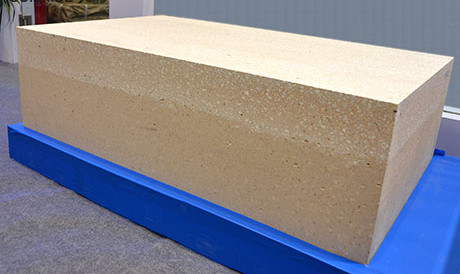

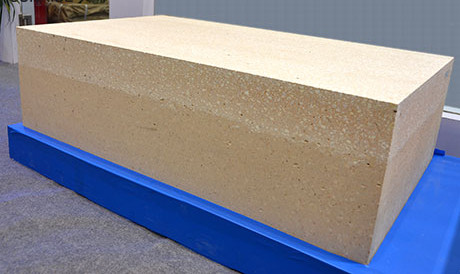

Fire clay block used for glass tank bottom adopts special refractory casting material vibration and molding process on high power vibration platform, uses high-quality Kaolin as raw materials. Its physical and chemical indicators and appearance are better than other similar products, especially much better than the traditional mud casting process and tamping process molding products in the anti-glass erosion performance. Particularly suitable for masonry glass melting furnace bottom, tank wall and other parts.

Advantages:

1. Low permanent linear change on reheating

2. High dense structure

3. Good Thermal Shock Stability

4. Good wear-resistance

5. Corrosion-resistant

6. Various shapes

7. High quality

| Item | Specifications |

| Al2O3(%) | 43 |

| Fe2O3(%) | 1.3 |

| R2O(%) | 0.8 |

| Refractoriness (℃) | 1750 |

| Soften temperature under T0.6 Load(℃) | 1450 |

| Reheating line changes(1400℃*2h) | +0.0 -0.4 |

| Apparent porosity(%) | 18 |

| Bulk Density(g/cm3) | 2.3 |

| Compressive strength (Mpa) | 50 |