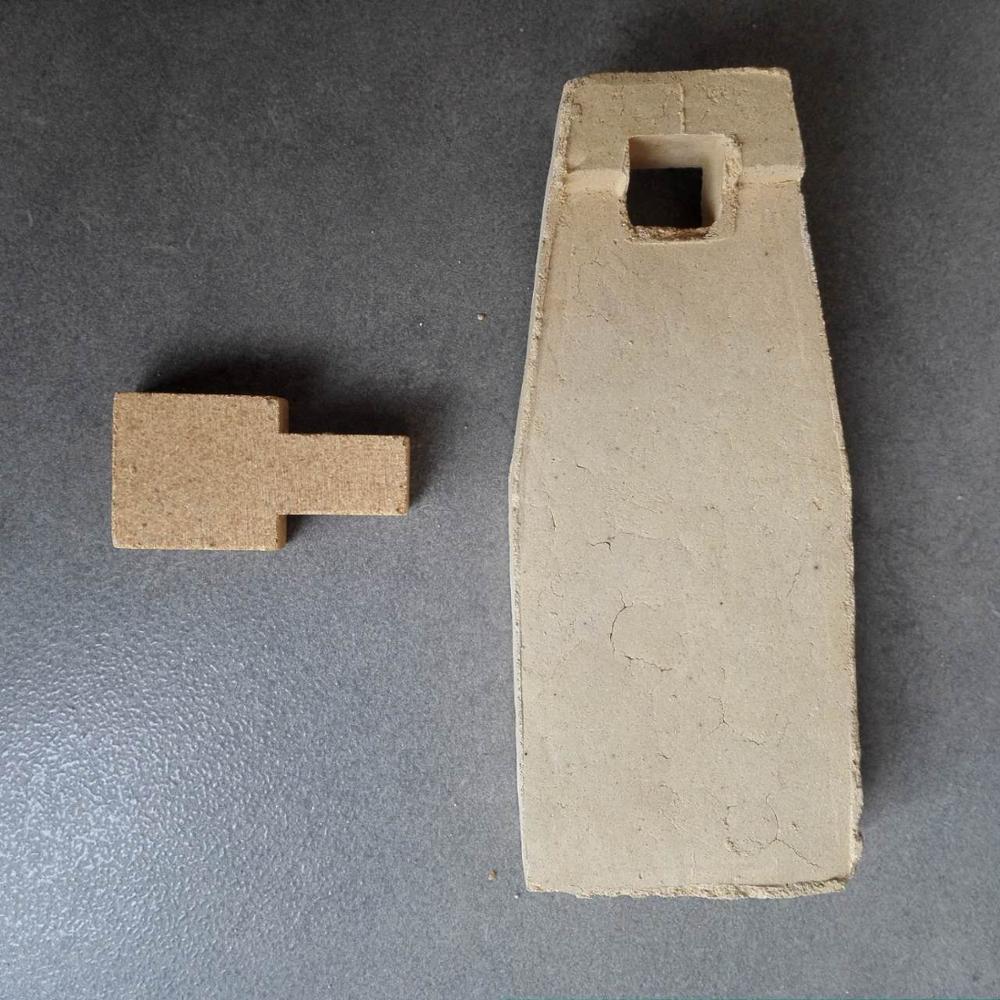

High alumina hook brick is a kind of refractory material with major component of AL2O3. High alumina hook brick is made by calcination of alumina or other high alumina content raw materials, with goog characteristics of high thermal stability, refractoriness can be above 1770 ℃. High-alumina hook brick is come from the shape of the refractory material, as the name suggests the shape of High alumina hook brick like hook so called high-alumina hook brick.

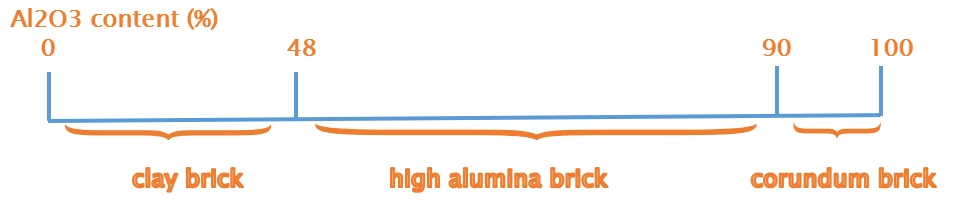

Various industries are not the same in the requirements to High alumina hook brick, as well as its classification, according to the shape, (Such as high-alumina hook brick, fan-shaped brick, etc.), alumina (Al2O3) content (such as Grade Ⅰ high-alumina brick, Grade Ⅱ high-alumina brick, etc.), characteristics(Such as micro-expanded High alumina brick, phosphate combined High alumina brick), process methods (such as firing brick, not burning brick, electric cast brick, etc.), raw materials (such as clay High alumina brick, mullite High alumina brick ), uses (such as High alumina brick used for blast furnace, High alumina brick for hot blast stove) and so on.

Application of high alumina hook brick

High alumina hook brick is mainly used for the connection of furnace wall and the wall and wall face wall and arch.

Hongtai produced high alumina hook brick use high alumina bauxite composed of water-containing aluminum oxide minerals (baitite, gibbsite, etc.)

high temperature high alumina hook brick

A. refractoriness

High alumina hook brick refractoriness is higher than clay brick and semi-silica brick, up to 1750 ~ 1790 degree, belong to senior refractory.

B. load softening temperature

Because high alumina hook products content more Al2O3, less impurities, less formation of fusible glass , so the load softening temperature is higher than the clay brick, but the mullite crystallization does not form a network organization, so its load softening temperature is still lower than silicone bricks.

C. anti-slag performance

High alumina hook brick contains more Al2O3, close to neutral refractory material, can can resist the acid slag and alkaline slag erosion. Because it contains SiO2, so the ability to resist alkaline slag resistance is weaker than acid slag resistance.

high temperature high alumina hook brick

Packaging of high alumina hook bricks

1.on wooden pallets with plastic cover: wooden pallet size :930*930 or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons

Shipping of high alumina hook bricks

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quanlity and quantity guaranteed, and also in accordance with the contract and customer's requirment completely.

1. Strong professional:

Our company has thirty years producing experience in refractory product. Our manager will supervise on a various refractory' s production materials, process control, quality supervision and package delivery, and ensure the products are 100% qualified.

2. Annual exports:

Now we have gained a global sales network reaching Taiwan, Russia, Mongolia, South Korea, Vietnam, Pakistan, Bulgaria, Finland, Greece, Spain, Congo, Angola, South Africa, and Maldives, Jordan and so on. The export figure is more than USD 4 million.

3. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

4. Testing equipment;

Our company's testing equipments as follows:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

1. How can I get your prompt quotation?

We can give you reply with quotation quickly if you kindly send the inquiry with the detail, such as the quantity, the specifications and the application of the products.

2. What is the MOQ (minimum order quantity)?

100 pcs is OK.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don't conform to customer's samples or have quality problems, our company will be responsible to make compensation for it based on enough evidences.

If you are interest in our products or relative refractories,contact us immediately.