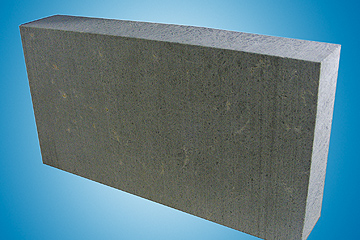

Application:

It is for SKID RAILs refractories of STEEL reheating furnace,

It is mainly used in areas that require high abrasion and temperature resistance, such as gliding rail bricks in steel pusher metallurgical furnaces, the tapping platform (tapping spout) style walking beam furnaces, and also as the interior for destructors.

| ITEM | Behaviors TY-GM20 | |||

Special | Typical | |||

Chemical Composition % | Al2O3 | 71-74 | 73 | |

ZrO2 | 19-22 | 20.5 | ||

SiO2 | 5-8 | 6.0 | ||

Fe2O3 | ≤0.5 | 0.3 | ||

Na2O | ≤1.0 | 0.5 | ||

CaO | ≤0.5 | 0.5 | ||

Apparent Prosity (%) | 5-8 | <8 | ||

True density g/cm3 | 3.0 | 3.55 | ||

Cold Crushing Strength Mpa | 250 | 350 | ||

Hot Crushing Strength 1300C Mpa |

| 120 | ||

Exudation temperature of Glass phaseC |

|

| ||

Line Expansion 1150C % |

| 0.9 | ||

Thermal conductivity 1250 C: W/MK |

| 9.2 | ||

Bulk Density (g/cm3) | PT(RN) |

| 3.0 | |

WS(VF) |

| 3.2 | ||

Crystallographic analysis % | Corundum | 71 | ||

Mullite | - | |||

Glass Phase: | 9 | |||

Baddeleyite | 20 | |||