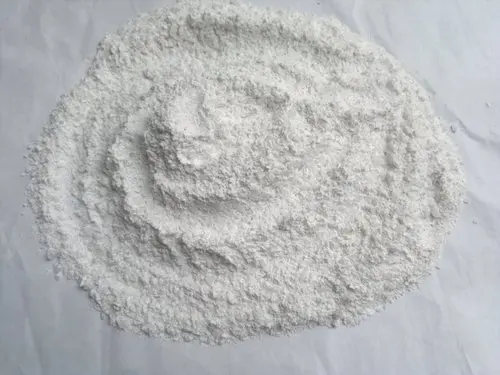

SIC acidic ramming mass used for blast furnace

SiC ramming mass is our best selling unshaped refractory material in Hongtai Refractory. We can produce kinds of ramming mass according to customer 's requirement.

Ramming mass is unshaped refractories using ramming (artificial or mechanical) method to construct, and heated and hardened in higher temperature than room temperature. It is mixed with a certain level of refractory aggregate, powder, binder, admixture with water or other liquid. According to the material, ramming mass can be classified to high-alumina, clay, magnesia, dolomite, zirconium and silicon carbide - carbon refractory ramming mass.

Features of SIC ramming mass

Chemical stability, resistance to erosion, anti-wear, anti-peeling, heat shock stability.

Application of SIC ramming mass

Ramming mass is used as filler to fill the furnace cooling equipment and masonry gap or masonry leveling layer, widely used in metallurgy, building materials, non-ferrous metal smelting, chemical, machinery and other manufacturing industries.

Note: Ramming mass baking, temperature raise should be strictly controlled , to prevent excessive temperature cracks.

SIC acidic ramming mass used for blast furnace

1. Strong professional:

Our company has thirty years producing experience in refractory product. Our manager will supervise on a various refractory' s production materials, process control, quality supervision and package delivery, and ensure the products are 100% qualified.

2. Annual exports:

Now we have gained a global sales network reaching Taiwan, Russia, Mongolia, South Korea, Vietnam, Pakistan, Bulgaria, Finland, Greece, Spain, Congo, Angola, South Africa, and Maldives, Jordan and so on. The export figure is more than USD 4 million.

3. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

4. Testing equipment;

Our company's testing equipments as follows:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

With stable and superior performance, our products are in great demand in more than 20 provinces and autonomous regions, and export to Russia, Brazil, Vietnam, Italy, South Africa, South Korea, Thailand, Singapore, Indonesia and other countries.

1. How can I get your prompt quotation?

We can give you reply with quotation quickly if you kindly send the inquiry with the detail, such as the quantity, the specifications and the application of the products.

2. What is the MOQ (minimum order quantity)?

100 pcs is OK.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don't conform to customer's samples or have quality problems, our company will be responsible to make compensation for it based on enough evidences.

Brand | GTD-1 | GTD-2 | GTD-3 | |

Main Chemical component

| Al2O3 | 50 | 60 | 65 |

SiC | 10 | 12 | 12 | |

C | 5 | 5 | 3 | |

MOR, MPa,≥

| 110℃*24h | 4.0 | 4.0 | 7.0 |

1450℃*3h | 6.0 | 7.0 | 8.0 | |

CCS,MPa,≥

| 110℃*24h | 20.0 | 20.0 | 20 |

1450℃*3h | 40.0 | 50.0 | 35.0 | |

PLC,%(1450℃*3h) | 0.5 | 0.5 | 0.5 | |

Application and characteristic | used for medium and small blast furnace lander, owning good construction performance, large strength and no viscous slag, can be used for mixture of mud, also add water to self-mix on fine material scene | Used for large or middle sized BF trough, with advantages like corrosion resistance, erosion resistance and high strength at high temperature | This material is colophonium combination, and it can be used for medium and small iron tapping blast furnace and can produce iron directly without firing | |