high chrome brick / chrome corundum refractory brick

Chrome brick is made of corundum and fused chromium oxide as the main raw material, together with powder additives, formed after mixing, molding, drying, and firing in the high temperature shuttle kiln.Chrome brick has good characteristics of wear-resistant, heat shock, acid and alkali erosion resistance, etc..

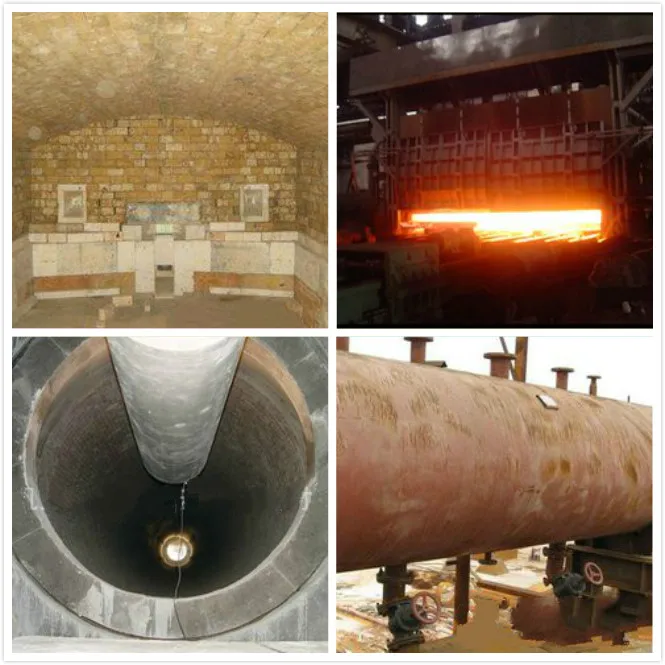

1. High chrome brick (Cr2O3 ≥ 90%) is mainly used for coal chemical industry, chemical industry furnace, alkali-free glass fiber kiln, waste incinerator and other key parts of the furnace;

2. chrome corundum brick is mainly used for the lining of carbon black furnace and copper smelting furnace, the tank of the glass furnace, the slide and tapping platform of steel rolling furnace.

finished high chrome brick

finished chrome corumdum brick

high chrome brick / chrome corundum refractory brick

Packaging of high chrome refractory bricks

1.on wooden pallets with plastic cover: wooden pallet size :930*930 or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons,

3.230*114*65mm:512PCS/Pallet, 230*114*75mm:448PCS/Pallet.

Shipping of high chrome refractory bricks

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quanlity and quantity guaranteed, and also in accordance with the contract and customer's requirment completely.