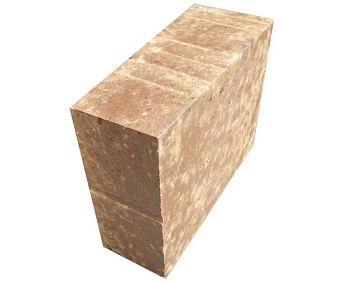

Silicon mullite brick is a fired brick composed of mullite (3Al2O3.2SiO2) and silicon carbide (SiC) as the main minerals. Its characteristics are that it has both the high temperature resistance of mullite and the advantages of silicon carbide, such as wear resistance and corrosion resistance and good thermal conductivity. When Baosteel was built in the 1980s, the refractory materials built into the torpedo-like container imported from Nippon Steel were similar to the current Silica bricks. In fact, it is a modified material of aluminum silicate products. The raw material of the molten iron tank is high alumina refractory brick. In the technological progress of the iron and steel industry, in order to speed up the speed of steelmaking, a certain amount of Calcium oxide (CaO) undergoes a so-called pretreatment. In this way, the refractory material in the tank has to withstand the high-temperature corrosion of molten iron and strong alkaline corrosion. Obviously, the high-aluminum material cannot withstand it, so adding an appropriate amount of silicon carbide to the high-aluminum material forms a new variety. The metallurgical industry calls it a fired brick of aluminum silicate combined with silicon carbide.

The performance of silicon molybdenum bricks comes from its process. First of all, the raw material needs to choose special grade bauxite with Al2O3 higher than 80%. The silicon carbide should be pure and the Mohs hardness should be close to 9.5. The company's selection of silicon carbide is very strict. This kind of mineral is extremely rare. Most of the products use SiO2 and C to synthesize SiC at high temperatures in an electric furnace. Different raw materials will produce different quality. At present, in the production process of SiC, SiO2 in the raw material comes from natural silica, and C is taken from coal coke and Petroleum coke, according to our research results, silicon carbide synthesized with petroleum coke and SiO2 has higher indicators in terms of hardness and wear resistance, and is suitable for use as silica mulberry bricks. The main crystalline phases of the fired bricks made from these raw materials are mullite, silicon carbide, and corundum. These minerals have high hardness, which lays the foundation for dense and high-strength refractory products.

Previous Post:Use of silica bricks

Next Post:Properties of silica bricks

Application of high-aluminum refractories in high-temperature industries

Classification of refractory properties and their application areas

High alumina bricks commonly used in industrial kilns