180TPD all-electric furnace in France

Glass manufacturer Verallia has fired up a €657 million all-electric glass melting furnace at its glass production plant in Cognac, France. With a daily output of 180 tons, the furnace is the world's largest all-electric furnace for food packaging.

Verallia CEO Patrice Lucas said that expanding the daily output of the all-electric furnace will enable the all-electric furnace to remain competitive in the food and beverage industry.

"This technology is not completely new, as it already exists in the cosmetics and pharmaceutical industries, but for food it is a world first."

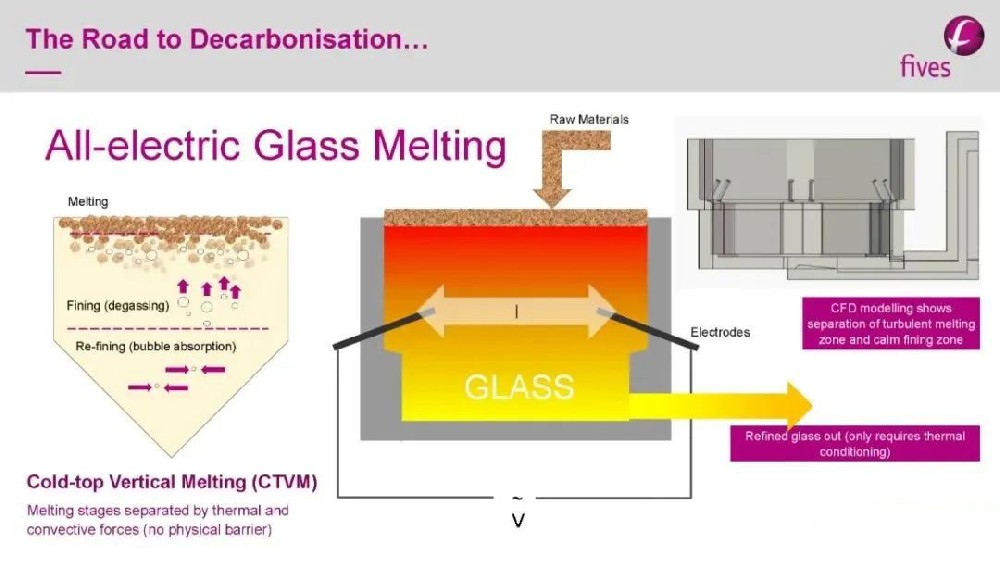

Verallia worked with industrial engineering group Fives on the project, which supplied the Prium E-Melt cold-top vertical melter.

The furnace will reduce CO emissions by 60% compared to traditional furnaces, in line with the Verallia Group's plan to reduce global emissions by 46% by 2030.

Lucas said this decarbonization goal was the main motivation for Verallia to choose low-carbon electricity over other fuel sources.

"All large industries have to face this energy transition. The only way to decarbonize is to move to electricity. What is good for the glass industry is that we have a solution to move our process to electricity."

The project started in March 2022 and was ignited on March 18, 2024.

Since then, Verallia has been increasing production to achieve 180 tons of flint glass bottles per day.

The furnace currently has a daily output of 150 tons, and the first deliveries to customers have just begun.

"We are currently ramping up to update all operating standards to achieve efficient production. Then we will look at the literature and discuss how to deploy this technology in other plants to achieve the 2030 CO2 reduction target."

450TPD Oxygen Furnace in Brazil

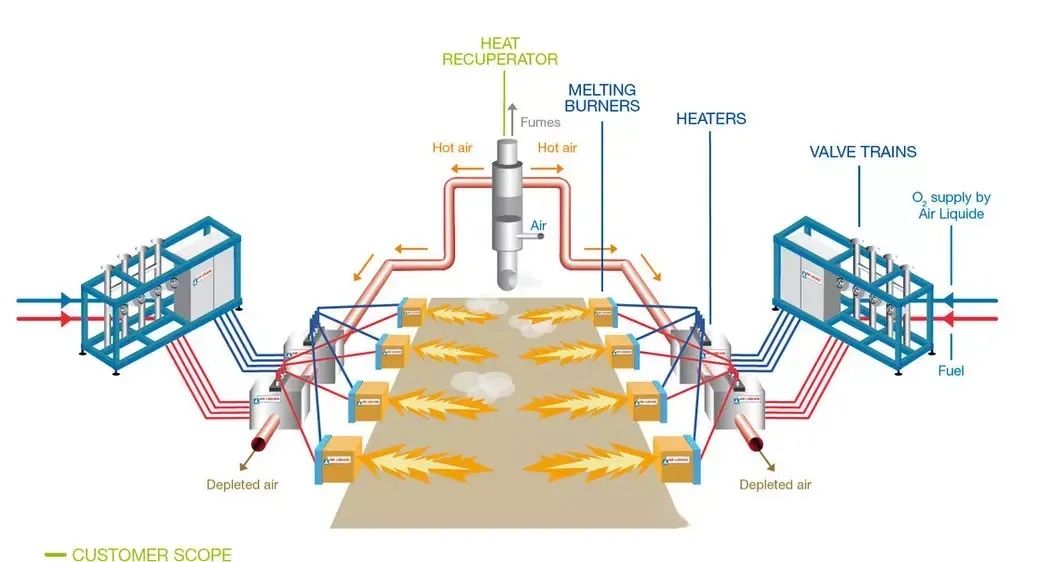

Verallia is also building a 450 ton per day heated-oxygen furnace at its Campo Bom plant in Brazil, at a cost of about €100 million. The commissioning of the furnace has been postponed to 2025 due to heavy rainfall in the Porto Alegre region of Brazil.

Despite the delay, the project is on track for launch in December 2022. The furnace will produce three colors: flint, green and amber and will be powered by heated oxygen.

The company considers this technology an “intermediate step” between traditional furnaces and Verallia’s decarbonization vision.

“The furnace will use HeatOx technology, a big advantage of which is that it reduces the energy required to melt the glass. In this way, we will reduce CO2 emissions by 20%.”

Previous Post:Development Direction of Induction Furnace Lining

Next Post:no more

Application of high-aluminum refractories in high-temperature industries

Classification of refractory properties and their application areas

High alumina bricks commonly used in industrial kilns